I rode with the bike train (me + 3 girls, tandem + tandem trailer down greenfield avenue unusually slowly on Friday (we had some extra cargo and it was unwieldy). VERY bottom of the hill, coming to a stop at the light the front tire gave out a loud hiss and was totally flat seconds later. Not my favorite moment, helluva haul back up the hill since my patch didn't work (aside, John in Greenfield, thank you, whoever you are). Glad it happened at such low speed, it could have been dangerous otherwise.

The rim was very hot. I'd been more cautious about the speed since we'd loaded things up a little more, and more awkwardly since the hope was that it was to be the start of a little trip. I think that heat was the cause since there was no tire damage or conspicuous bump on the way down and I'd checked pressure just before leaving.

I don't know but am assuming that retrofitting additional braking would be a very expensive proposition, and I'm actually kinda ok with the power I'm getting. The simplest answer is change no equipment to stop mid descent for a minute and/or change route to the road oriented rather than trail oriented so we don't burn up all the vertical at once. I may do these anyway, but am looking for supplementary ideas, if any are easy.

Off the top of my head I'm wondering whether I need different brake pads, if the thick, thorn resistant tubes buy me a little more time before they turn to goo, or if there are any tricks people would recommend, unusual or not so unusual stuff to sub in for the stock rim tape (which is just a little rubber strip covering the spokes) that might be a useful barrier against the heat.

byogman

2015-07-05 21:58:25

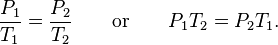

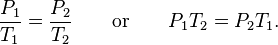

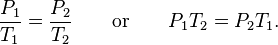

The cause is heat. Pressure goes up as temperature goes up -- the famous

Gay-Lussac's law

. So what happens here is that you put some air in your tire, I would say close to maximum one, I would guess you have an aluminum rim (aluminum has excellent heat conducting coefficient), so while breaking a lot of heat got transferred to tube and air and two things happened:

1. Air pressure went up significantly exceeding maximum one;

2. tube started to lose some strength due to high temperature (butyl tubes are stronger than natural latex one -- the natural one are going to melt much earlier).

And usually tube gives up just around valve.

mikhail

2015-07-05 23:19:33

For moderate cost, you could swap out the front fork for one equipped with disk brake tabs (unless you're lucky enough to already have them on the existing fork), and add a mechanical disk. That way, you can re-use your existing brake lever.

I'm currently contemplating the same thing, as my tandem+trailabike train also uses rim braking.

reddan

2015-07-06 05:52:28

That's right it is heat. riding the brakes down a hill makes the rims very hot. you could let out a lot of air and run on the minimum safe pressure for the descent and then pump them back up. also carry spare tubes. you can still patch when you get home.

neilmd

2015-07-06 06:26:32

A tandem site I looked at suggested using cotton rim tape instead of rubber/synthetic since it doesn't transfer heat as quickly, but mostly they suggest either a drum or disk brake add on. Or you could use the Fred method.

marko82

2015-07-06 07:34:34

Seems to me that some sort of home brew version of

this might appeal to you.

There's also this article from Jobst Brandt on what happened to you:

http://sheldonbrown.com/brandt/blowouts.html. The article mentions gauze-like rim strips "filled with Kapok" (a fibrous plant material) for preventing this. I would imagine you are already thinking of a way you could work up something like that.

jonawebb

2015-07-06 07:50:24

Without question brakes that don't involve friction on the rim are best; disk brakes also are just plain effective.

neilmd

2015-07-06 08:01:57

I had this same problem when riding down Syncamore with other people/traffic. The solution was Velox rim tape for me. It's only a couple of bucks, so if it doesn't work for you you're not out too much. It's made out of canvas or something, so it's a good insulator between the hot rim and the tube.

Just make sure you get the right width to cover the area of the rim the tube will be in contact with when a tire is installed.

With the plastic/rubber rim strips, I would lose a tube EVERY TRIP when I was riding with someone who needed me to go slower down the hill.

mattjackets

2015-07-06 08:15:15

Matt, thanks for the el cheapo experiment, will be making it shortly.

Dan, I'd like to solve this the right way, I was having no trouble finding affordable disc forks, but was having a lot of trouble finding affordable forks that said that they were tandem rated. We're a light team in terms of weight on the fork, so maybe I could get away with it, but was trying to not do anything questionable AND spend any real money on it at the same time. Besides, in addition to a new fork and brake obviously, don't you need a totally different wheel? Also having trouble finding something that says tandem and disc and isn't very expensive there.

byogman

2015-07-06 09:03:44

Perhaps the most likely to be effective cheap solution is to replace the rim tape with some kind of heat insulating tape. There are lots of different types available, for example

http://www.firesleeveandtape.com/high-temperature-heat-flame-fire-pyro-resistant-tape-wrap-wire-cable-hose-protection-group.html. I would also use a tube with a long valve to get the rubber there as far away from the rim as possible. Maybe wrap the valve itself in insulation. I suspect if you isolate the tube from the rim pretty well you'll be able to get through a downhill run OK.

jonawebb

2015-07-06 09:30:32

I wonder if adding some "Green Slime" flat-proofing goo to the tube would add some cooling mass? Worst case scenario you have added some puncture resistance.

edmonds59

2015-07-06 09:32:45

Wouldn't the green slime end up on the outer edge of the tube? Too far away from the heat source to have much effect, I'd think.

Oh, one other thing -- you can squirt water from your water bottle onto the rim. Obviously this will be somewhat counterproductive since it will temporarily reduce braking efficiency but in my experience that effect is pretty short lived.

jonawebb

2015-07-06 09:35:00

Yes, you'd need a disk-compatible wheel.

If it were me, I'd treat this as a question of "what's the least I can spend to upgrade to a proper braking system?", rather than "what can I do that's inexpensive and may or may not be effective?". I'd not choose to experiment with heat shielding of unknown efficacy when hauling precious cargo.

A used disk wheel should be fairly easy to come by...as far as the fork goes, maybe call Ambridge Bike Shop and see if they have anything floating around? They (used to) carry a lot of tandems, and may either have something cheap or have other suggestions (like a drum-brake rear wheel, perhaps).

Regardless of what you choose, please keep me posted, as I have similar concerns.

reddan

2015-07-06 10:04:00

This is a pretty common concern for tandem riders.

I think you've gotten some good advice. The pressure increase due to the heat wasn't the likely cause. You might have gone from 300K to 400K in temperature, which would have increased pressure from maybe 90 psi to 120 psi. If you had a pressure related failure it would likely have been a catastrophic blowout. You didn't mention where the tube ended up failing, though. If you had a cheap rubber rim strip, I wouldn't be surprised if it is was a hole caused by the rim strip softening and deforming into a spoke hole. Velox rim tape would help in this situation, but you aren't going to get any real insulating value from the rim strip. You will get additional strength, though.

Without changing fork, wheel, or adding a drum brake, changes in riding behavior are your best bet. The worst way to descend, heat wise, is medium and steady. That loads up the heat without a lot of airflow to dissipate it. Fast and little braking is the safest from the standpoint of rim heating. Slow with some stops to cool off the rims would be next. When I take the big bikes (tandem and triple) downhill, I sometimes alternate which brake I use to give each rim time to cool off. I also will brake hard, then allow the bike to roll, and then brake hard again, to maximize speed reduction and minimize time the brakes are being applied. Changing routes, when possible, is also a viable alternative.

Ultimately, now that you are aware of the issue you can determine the best way to deal with it for you. Pittsburgh, while hilly, doesn't have the really long mountain descents that can cause this issue to be a major concern. I don't think you need major hardware changes, though, although you need to decide for yourself how you want to change things.

abm760

2015-07-06 11:03:42

Just put a mechanical disc brake up front and stop taking chances with your kids' safety; surely they are worth whatever a fork, wheel, caliper and disc would cost. I can't imagine that special rim tape, thicker tubes, or any other half-assed, band-aid fix will give you enough of a margin of safety to do what you are trying to do with that bike. You are asking those brakes to handle two extra people and two extra pieces of equipment. I feel pretty confident that the extra weight is well beyond what those brakes are intended to stop - which is why you were creeping down the road in the first place, correct?

jmccrea

2015-07-06 11:15:09

I agree that disc brakes are the best way to go. But ragging on @byogman about not doing everything he can to protect his kid's safety is misplaced. If you follow that argument to its logical conclusion, he would end up driving around in a big heavy SUV. So he's trying to make a sensible compromise given his inclinations and budget. And, really, just keeping the rim from overheating the tube would fix this particular problem.

jonawebb

2015-07-06 12:05:55

Money being no object, what would it cost to rig up a brake for the trailer systems? I can see this same concern if pulling any trailer with a non-trivial load, and human life notwithstanding, if whatever that cargo is on said trailer, if it's valuable, it's valuable enough not to lose it in a wreck caused by a blowout from an overheated brake. This cannot be a new problem.

IOW, there must already exist some technology that solves this problem, even extending back to the second trailer. They've had it on tractor-trailers and railroads for over a century.

stuinmccandless

2015-07-06 12:38:26

@stu: Off the cuff, if manual operation is acceptable, I'd probably start with a hydraulically actuated brake (are hydraulic drum brakes a thing?) on the trailer's rear wheel/wheels, and a long hydraulic hose leading to an additional lever on the rider's handlebars. This could be operated like a traditional tandem drag brake, I'd assume.

For automatic operation, I 'm not sure where to begin...some form of mechanical or electronic pressure sensor on the trailer hitch, detecting that the trailer is applying undue force to the (presumably slowing) bicycle?

A spring-loaded plate with brake cables wired to it, which tightens the trailer's brakes as it's driven backwards by pressure on the hitch?

A Bluetooth module which connects to your phone and uses Strava data to decide when to brake? (Kidding...)

reddan

2015-07-06 12:52:34

How about a mechanical on the tire like the old fashion spoon-brake on highwheelers?

But seriously, we don't live where long steep descents are all that common. I'd try the new rim tape and follow the braking strategies @abm suggest. Now that you know heating can be an issue you can be extra cautious of how long you are braking and stop as needed. Your kids will outgrow the trailer soon enough.

marko82

2015-07-06 13:30:13

We went through a lengthy design discussion on how to have passively activated brakes with @byogman's trailer system (

here). I think we ended up concluding that this sort of brake (I think it's called a "surge" brake) would be expensive to implement.

Another option that came up at the time was a kid operated brake. I think this might work for @byogman, because his kids seem pretty damn cooperative.

I personally think the idea of this lengthy bike train is kind of dangerous, more for @byogman than for any of his kids. Coming down the Pinkerton tunnel detour one time, pulling a trailer, I found myself going faster and faster without being able to stop. Finally I crashed, fortunately before going over the hill into a steep gorge. Something like that could happen to @byogman pretty easily if he got going too fast down a steep hill, I'd guess.

jonawebb

2015-07-06 13:37:56

Hi guys, figured it was time to check in again.

Were that kraynick's had what I needed, reddan's suggestion would be a no brainer. Even one of the other local shops, if I were paying retail but it all JUST WORKED, it'd be a serious consideration. Picking and piecing together online, I'm just as likely to wind up buying stuff with incompatible sizing, geometry, or who the hell knows what else.

I was being a little extreme with keeping the speed down there due to the load not being as low as I wanted and there being some cross wind. I was not pulsing as I should have been doing. And it was more heavily loaded than is usual and the failure happened only at the very end without any stop to cool things off, and this on the most continuously brake heavy route downtown. I'd even, just before, inflated the tires to the higher end of the range.

In short, I was a bit dumb. There are a lot variables there I can control to make this less likely, and I plan on controlling a couple of them at once, not just stuffing the rims with some better, more insulating stuff, though that is another part of the plan now.

Keep in mind this is really only a plan for a fairly short period, with frequency tapering significantly when my oldest starts school in less than two months. Next riding season, if the middle girl is tall enough for the tandem, the oldest will be booted off bringing things well back into the normal range for the tandem's brakes, even including that crazy trailer.

And even if not, how often do I go downtown with all of them? Not really all that much. Spending more than I did on the tandem or the trailer to avoid, worst case, a two minute stop on occasional downtown trips for, worst case, a season and a half is not really cost effective enough to be reasonable in my book. Would rather invest that in getting my eldest something nice to ride on herself.

byogman

2015-07-06 15:10:12

My older daughter now 17 revealed at some point that she used to drag a stick on the ground out of the trailer to see how much it would slow me down. She really is gonna be an engineer...

neilmd

2015-07-06 21:34:20

The idea of taking apart the wheel of the weehoo igo 2 and putting in a two speed automatic hubs with a coaster brake has definite appeal. Make peddling useful in a little broader range of circumstances and provide another source of braking (and yes, I'd expect shenanigans once or twice, but a couple stern talks should do). But I don't know whether that might be a huge job or just impossible with the spacing, I wish the spread between the gears were larger, and I don't know if the next would be owner of the trailer would really consider all this tampering a plus. For sure, REI wouldn't take it back if I had a problem...

byogman

2015-07-07 09:36:18

Here you go Reddan. I expect to see some version of this at Pedal Pgh.

edmonds59

2015-07-07 15:47:46

This is for whatever it may add to the discussion:

I don't think surge brakes would be a great choice, despite the fact that, in theory, you could build a functioning system for a bike trailer. Hydraulic surge brakes are used almost exclusively on boat trailers; electrically operated trailer brakes are otherwise the norm. Why? The surge brakes endure being submerged in water much better than the electromagnets, etc. in electric brakes. Surge brakes also don't need to be - and as I understand them are not - readily adjustable for varying loads, unlike electric brakes. A boat trailer is either empty and needs no braking, or it's carrying a load that varies only by how much fuel, food and alcohol the boaters have loaded into the thing - largely insignificant factors. Thus, an engineer can size the master cylinder, drum size, etc. for a given weight, center of gravity, and whatever other principles of physics may be at play.

Even if the weight on a bicycle trailer were always the same, I think it would take a bit of trial and error to get the braking power produced to match up with the braking power needed. Designing a self-actuating cable system is no big deal (see above for a fine example); keeping it adjusted to apply the same power to each wheel, at the same time, may be challenging.

Here is what I would do if I wanted a brake system on a bike trailer: Get a hydraulic front brake master cylinder from a motorcycle and put it on the bike, but make it easily removable. Run a kevlar braided hydraulic line back to a junction block or a "T" on the trailer. From the T, run two lines out to hydraulic Wilwood billet spot calipers (one on each wheel), and have the calipers grabbing 185mm mountain bike discs. Somewhere in there you'll need a bunch of fittings to convert the banjo fitting on the master cylinder to perhaps -3 AN lines, then ultimately to internal NPT threads at the calipers (if I recall correctly). Believe it or not, this is probably the easiest way to do something like this, unless you can make custom lines and find a junction block for whatever hydraulic lines MTB disc brakes use (some sort of metric internal flare or compression fitting, if I had to guess).

jmccrea

2015-07-07 17:05:08

If everything goes according to plan, I'll be hauling about 300+ pounds of cargo in a month on a Surly Bill trailer. In my brief conversations with Thick, and looking around on the Internet, the consensus seems to be that my bb7s with some upgraded 203 rotors, sintered pads, and a new fork (since mine is kind of damaged, and I don't think designed for larger rotors) should do the trick.

I'll probably get a Big Dummy fork (about $100), which can take disc or cantilever brakes, and I imagine, is designed to be pretty strong, since the bike it comes from can handle 200 pounds of cargo.

sgtjonson

2015-07-15 12:43:50

Please report back. I got a mountain bike with decent sized, though not premium discs, that will be my cargo trailer hauler. Debating whether to go big on said trailer or not.

byogman

2015-07-16 08:47:39

. So what happens here is that you put some air in your tire, I would say close to maximum one, I would guess you have an aluminum rim (aluminum has excellent heat conducting coefficient), so while breaking a lot of heat got transferred to tube and air and two things happened:

1. Air pressure went up significantly exceeding maximum one;

2. tube started to lose some strength due to high temperature (butyl tubes are stronger than natural latex one -- the natural one are going to melt much earlier).

And usually tube gives up just around valve.

. So what happens here is that you put some air in your tire, I would say close to maximum one, I would guess you have an aluminum rim (aluminum has excellent heat conducting coefficient), so while breaking a lot of heat got transferred to tube and air and two things happened:

1. Air pressure went up significantly exceeding maximum one;

2. tube started to lose some strength due to high temperature (butyl tubes are stronger than natural latex one -- the natural one are going to melt much earlier).

And usually tube gives up just around valve.  . So what happens here is that you put some air in your tire, I would say close to maximum one, I would guess you have an aluminum rim (aluminum has excellent heat conducting coefficient), so while breaking a lot of heat got transferred to tube and air and two things happened:

1. Air pressure went up significantly exceeding maximum one;

2. tube started to lose some strength due to high temperature (butyl tubes are stronger than natural latex one -- the natural one are going to melt much earlier).

And usually tube gives up just around valve.

. So what happens here is that you put some air in your tire, I would say close to maximum one, I would guess you have an aluminum rim (aluminum has excellent heat conducting coefficient), so while breaking a lot of heat got transferred to tube and air and two things happened:

1. Air pressure went up significantly exceeding maximum one;

2. tube started to lose some strength due to high temperature (butyl tubes are stronger than natural latex one -- the natural one are going to melt much earlier).

And usually tube gives up just around valve.